We provide automatic assembly equipment for a wide variety of fields, from small batteries for consumer use, including laminated, cylindrical, square and coin-shaped, to large automotive secondary batteries and automotive parts for electric vehicles (EVs) and hybrid vehicles (HVs). We also suggest line components as appropriate according to customers’ needs, including entire assembly lines based on factory layout and systems combining assembly by machines with robot-based assembly, thereby helping customers solve their issues and improve productivity.

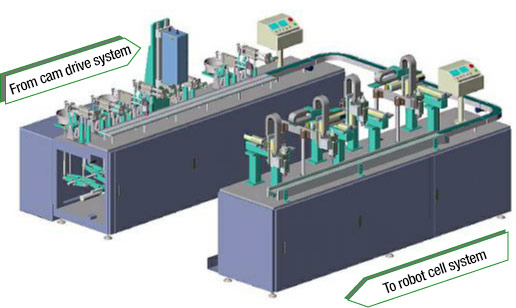

Cam and linkage mechanism model

Automatic assembly system that uses cam and linkage mechanism

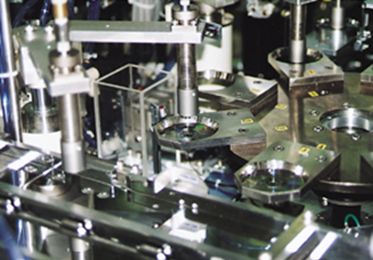

Automatic assembly systems are essential to ensure high efficiency (high productivity), which is enabled by mass production technologies conforming to product development.

We cater to those needs with our extensive experience, expertise in technologies for high-speed assembly and engineering capabilities.

We ensure the stable operation of equipment with our experience and technologies accumulated over many years of commitment to automatic assembly. Therefore, we contribute to productivity improvement and high-quality assembly.

We can suggest systems that combine mechanical assembly, such as assembly by cam and linkage mechanism and servo cylinder mechanism, with robot-based assembly, as appropriate according to the customer’s situation.

Use of a simple control program enables workers to operate the system easily. In addition, our systems are designed to operate silently, reducing noise emitted to the neighborhood.

Due to the cam and linkage mechanism, annual power consumption of our systems is lower than conventional assembly equipment consisting of cylinders. They also permit smaller dry rooms, contributing to saving energy throughout the entire facility.

We have also delivered products to many customers in fields other than batteries and automotive parts.

Contact our sales team for details.