Predictive Diagnostics Solution

Predictive Diagnostics Solution

Supporting the improvement of production efficiency by maintenance management and the stable operation of equipment.

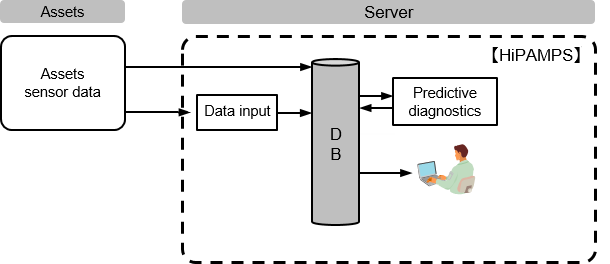

HiPAMPS*1 analyzes sensor data collected from equipment and detects unusual statuses.

The predictive diagnostics solution is one of the maintenance support services that offer high added values to our customers and society through communication between equipment, people and things via the IoT*2.

Using new IT*3 analytics and the findings from OT*4 technologies we have accumulated through the manufacturing of our products and maintenance services, we provide predictive failure diagnostics, which prevents the unexpected stoppage of equipment.

Through this service, we contribute to securing the efficient and stable operation of customers' equipment and newly support customers' operations in accordance with maintenance, operation and management needs.

This diagnosis combines IoT and our patented technologies for equipment monitoring and analysis of collected operation data. With these functions, this diagnosis detects unusual variations in the equipment status, prevents unexpected stoppage of operation, achieving stable operation of your equipment. With this technology, we contribute to the reduction of maintenance costs by enabling inspections at the appropriate time, and the maximization of equipment performance by grasping of the overall status.

Patent No. : JP 4832609

This diagnosis creates a database of collected past data and past failures and maintenance information. In addition, if any unusual status is detected, it is collated with information stored in the database, displaying the predicted cause. This function supports appropriate and immediate maintenance responses. Upon customer request, we will propose improvement measures for the equipment status by fully utilizing our findings accumulated over many years through our manufacturing and maintenance service experience.

Patent No. : JP 05753286

We propose a very accurate predictive diagnostics service suitable for the customer equipment environment and needs by carrying out validity evaluation of the predictive diagnostics system with sample data as well as verification tests utilizing actual equipment to examine issues that occur in customer equipment. We will support your introduction of this highly accurate predictive diagnostics system based on practical use by producing and evaluating learned data of the equipment operation statuses and providing proposals for systems with high operation effects.

We will support the realization of status monitoring and maintenance for appropriate maintenance performed in accordance with equipment status. In addition, we will contribute to the prevention of the unexpected stoppage of equipment operation and reduction of maintenance costs.

We will consult with customers and implement a survey of customer equipment to provide appropriate services.