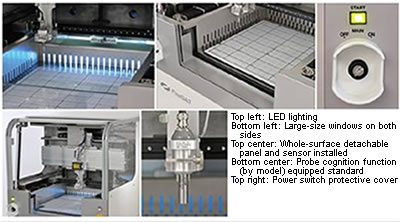

(equipped with the option in the photograph)

The Scanning Acoustic Tomograph FineSAT uses ultrasonic waves to obtain images of internal voids, cracks, abrasion, etc., in materials such as semiconductor packages, electronic components, ceramics, metals, resins, in a non-destructive manner. FineSAT can also detect nanometer gaps that cannot be detected by X-ray equipment, infrared inspection equipment or optical microscope.

FineSAT Ⅲ, the third-generation equipment of FineSAT, has the best performance for basic functions such as high resolution, and it is equipped with the most enhanced analysis software that provides high-speed auto measurement, transmission/reflection simultaneous measurement function and defect auto-detection function. Furthermore, it has improved usability, including batch storage of flaw-searched data, and can be used in a wide range of applications; from large amount inspection in the production process to research and development.

A mechanism that prevents mechanical and electrical accidents is provided by default, for example, an area sensor is installed to prevent erroneous operation in the case of wide openings that are convenient for placing and removing samples.

FineSAT is fully equipped with items such as a magnetic plate that facilitates securing small samples and a standard test specimen that is essential for daily inspection. In addition, we are meticulously responding to improvement needs during daily operations in the software, including the enhancement of the help functions.

We introduce new ideas in different details so that the equipment is easy to use with safe operation; some example are the large windows on both sides, LED lighting, power switch protection cover, detachable front transparent panel, etc.

We have an abundant lineup of probes for the reflection method that fit the objects and conditions of measurement, from low to high frequencies and from short focal length to long focal length, and of probes for transmission method. Our customers therefore can find appropriate probes for their object of measurement. We also support customers in selecting the appropriate probes.

For FineSAT, the analysis software for waveform analysis, measurement, abrasion judgment and depth information has been further enhanced.

By using the software, the data of ±phase, absolute intensity and depth are comparable on a real-time basis. In the overlapped-waveform display, the different time axis can also be adjusted and stored automatically. The data of the unique inter-pixel interpolation process and automatic contrast control are made viewable and obtainable.

In a multiple gate function, up to 64 gates can be set up. Both the data and the measurement conditions are stored together in each gate, and the image data with a single file is a standard feature of the software.

Furthermore, the function that retrieves all-point waveforms, changes the gate position offline and redraws the image is also equipped as standard.

When the volume scan function (optional) that enables FFT analysis and difference imaging process is equipped, more stereoscopic ultrasonic image data can be constructed by adding the 3D viewer software (optional), which strongly supports the analysis of internal structure.

Displays the profile of reflection intensity and depth simultaneously for a combined evaluation.

Comparatively analyzes ±phase, absolute intensity, depth, polarity emphasis in real time.

3D viewer software (optional)

Restores and visualizes the shape in 3D, rotates the image 360o in both horizontal and vertical directions to enable observation from an arbitrary viewpoint, and sectional display at an optional position.

| FS100Ⅲ | FS200Ⅲ | FS300Ⅲ | |

| Probe frequency (MHz) | 5–75 | 5–140 | 5–300 |

| Effective stroke (X × Y × Z) (mm) | 350 × 350 × 80 | ||

| Maximum scanning speed (mm/s) | 1,000 [Nominal value] | ||

| External dimensions (W × H × D) (mm) | 1,590 × 1,340 × 940 | ||

| Weight (kg) | Approx. 380 | ||

| Power supply (voltage/current/frequency) | AC100V/15A 50/60 Hz | ||